davi mcp 3 roll double pinch section benders

Davi MCP – 3-Roll Double Pinch Angle Roll

The Davi MCP – 3-Roll Double Pinch Angle Roll Machines are designed and manufactured with the end user specific products in mind. Some types of production do not need a high precision, but some types do, and they need accurate repeatability. Davi manufacture a basic range of machines that can be configured with a range of different options to achieve the best solution for the customers production. All Davi MCP’s can be installed with shafts, horizontal or vertical. With the aid of FEM technology, Davi have analysed the frames of the MCP range, thus have eliminated the unnecessary critical stress points on the frame. With planetary movement of the side rolls, the tightest diameter possible is achieved. The overall length of the shafts were decreased, this eliminated the overhang, which made the shafts more rigid, again reducing stress on the shafts. The guide arms move in 3 dimensions vertical, horizontal and forward/backwards, helping guide the section through the forming stage.

Three independently driven shafts

All three shafts are driven independently by hydraulic motors. No large expensive gear that are prone to failure due to high stress. Individual drives help with better options for increased accuracy .

Direct roller drive from shaft

Each roller is driven directly by its shaft via a direct spindle. Giving better control for the forming of the customers section, minimising failures. Again, benefit of high torque can be achieved.

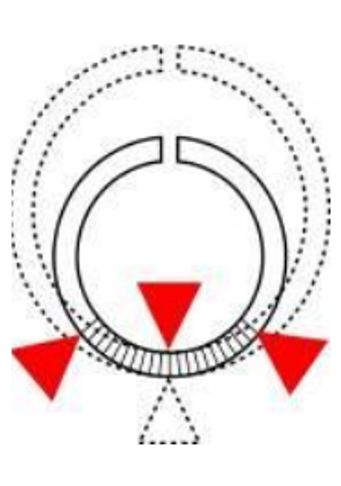

Planetary Guides for minimum diameter possible

Planetary Guides for minimum diameter possible

Planetary Guides for minimum diameter possible

The planetary roll drive pushes the section closer to the top roller. The minimum diameter achievable is increased.

Guide roll position

Planetary Guides for minimum diameter possible

Planetary Guides for minimum diameter possible

The guide arms have three movements which help position the guide rolls as near as possible to the type of section being formed.

Shafts with no overhang

Planetary Guides for minimum diameter possible

Shafts with no overhang

The 3 main rollers are now positioned as close to the frame as possible. The stress is now on the frame and not on the shafts

davi mc4p four roll section benders

DAVI MC4P FOUR ROLL SECTION BENDERS

The Davi MC4P – 4-Roll Angle Roll Machine was developed for specific operations where a standard 3 roll machine wasted too much material. As with the 3 roll section bender, the 4 roll machines are designed and manufactured with the end user specific products in mind. Some types of production do not need a high precision, but some types do, some need accurate repeatability. Davi manufacture a basic range of machines that can be configured with many different options to achieve the best solution for the customers production. All Davi MCP’s can be installed with shafts, horizontal or vertical. With the aid of FEM technology Davi have analysed the frames of the MCP range and thus have eliminated the unnecessary critical stress points on the frames. With planetary movement of the side rolls, the tightest diameter possible is achieved. The overall length of the shafts were decreased, this eliminated the overhang, which made the shafts more rigid, and again reduces stress on the shafts. The guide arms move in 3 dimensions vertical, horizontal and forward/backwards, helping guide the section through the forming stage.

Four independently driven shafts

As with the 3-roll angle roll, the 4-roll machine has all four shafts driven independently. No large expensive gear that are prone to failure due to high stress. Individual drives help with better options for increased accuracy.

Four roll technology on a Section Bender

With the aid of the forth roll on a section bender, the section can be pinched between the top and bottom rollers. The prebend is then carried out by the side roller, reducing the flat down to virtually nothing.

Plate roll - section bending - cnc cutting - hydraulic press

Our Partners

Stone's Machine Sales & Cutting Service

Unit 36 Mildred Sylvester Way Normanton Industrial Estate Normanton West Yorkshire WF6 1TA

Copyright © 2025 Stone's Machine Sales & Cutting Service -

All rights Reserved.